Advantages of high-quality glued laminated timber:

- Excellent thermal insulation properties.

- High ecological safety, as only high-quality adhesive compositions are used in the production of glued timber.

- Preservation of the geometric shape of the structure for many years and almost complete absence of shrinkage (high-quality material retains its shape throughout the entire period of operation).

- Increased fire resistance (achieved through treatment with special materials).

- Seismic resistance and strength allow glued laminated timber to be used for the construction of wooden houses worldwide.

In our wooden houses, the customer can choose the grade of glued laminated timber: the first or the highest grade.

THE TECHNOLOGY

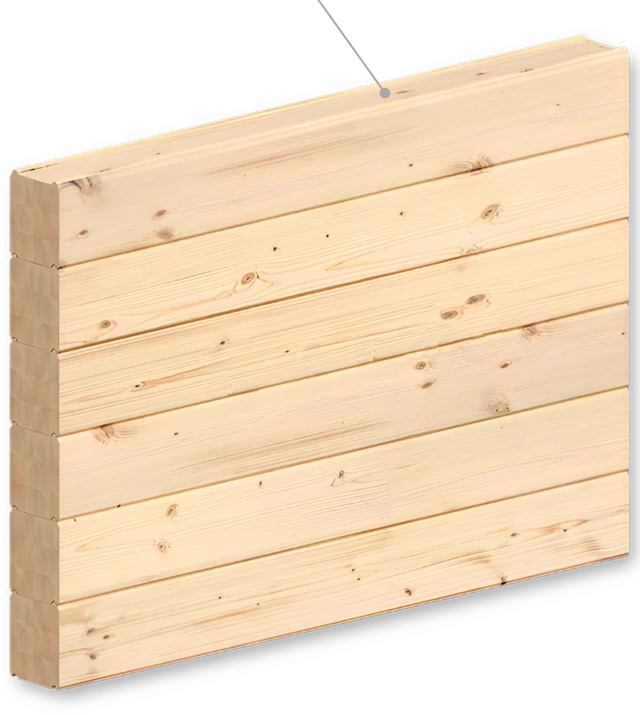

laminated timber

SORTING, SAWING

The process of manufacturing a wooden house begins even before it reaches the factory. Forestry specialists carefully select pine logs with the appropriate characteristics suitable for manufacturing purposes. These logs are then delivered to the factory and proceed to the first stage of producing glued laminated timber, which involves sawing the logs.

Gluing

Gluing is one of the most important stages in the production of glued laminated timber, requiring not only high-quality raw materials, but also control of temperature and humidity in the premises. The use of 12-meter presses for load-bearing structures with a pressure of up to 18 kg/cm2 allows the production of high-quality wooden houses.

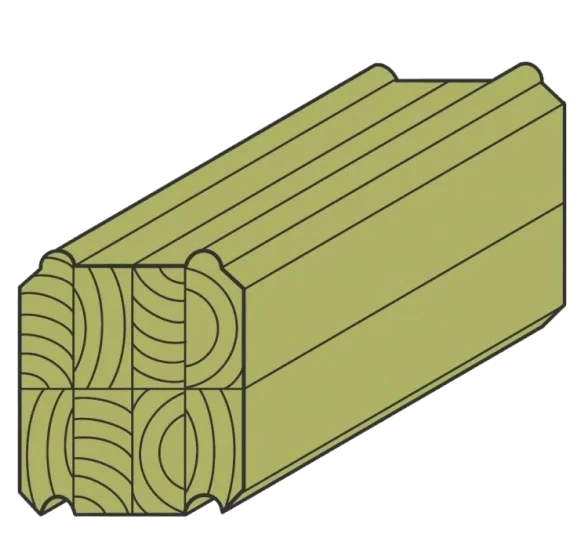

Profiling

The patented profile of glued laminated timber allows for the construction of wooden houses without the use of insulation between logs, thanks to the unique profile feature and equipment precision. Powerful modern equipment can profile glued timber with a cross-section up to 300x400 mm.

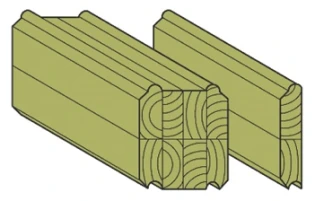

CUTTING OF CORNER JOINTS

Manually positioning of the logs, high-quality milling cutters and specially designed equipment make it possible to perform joints of any complexity and any angle with high precision.

In the end, after conducting quality control checks, our glued laminated timber

is a completely ready-to-assemble element of your future wooden house.

INSULATED

Thanks to the efforts of our partners' engineers, a fundamentally new type of glued timber has been developed for building wooden houses. This type of log combines the thermal technology of a frame house with the aesthetics of a solid glued timber. The innovation lies in the fact that there are special cavities inside the log that can be filled with insulation such as foam or other types of foam insulators. Due to the advanced technology, it is practically impossible to distinguish externally between a construction made of hollow logs and one made of solid glued timber, unlike construction according to the block-house technology.

The presence of cavities allows for:

- Significantly simplifying the installation of all utilities in the house (electricity, water supply, drainage, etc.).

- Reducing the weight of the structure, which positively affects the installation time and complexity.

- By using special foam insulation, it is possible to increase the thermal resistance coefficient several times, which makes it possible to save on heating costs.

GlUED

Glued wooden beams are used for making floors – a structural part of a building that separates it into different floors. They have a moisture content of 10-12% across the entire cross-section. They have a stable geometric shape and do not transform or crack, unlike solid wooden beams. This material has a higher strength and load-bearing capacity coefficient than solid wooden beams.

Glued wooden beams are not limited in size, which allows for spanning large gaps and structures. The advantage of this material over steel or reinforced concrete beams is its low thermal conductivity and small specific weight.

They are the most reliable material for rafters as the supporting structure of a pitched roof. Rafter plates serve as the lower support for the rafters and are intended for load distribution in the floors. Glued wooden beams are also used as support pillars and other load-bearing elements.

Glued wooden beams simplify the installation of structures, thus finding wide application in the construction of complex roofs (ice rinks, shopping centers, waterparks).

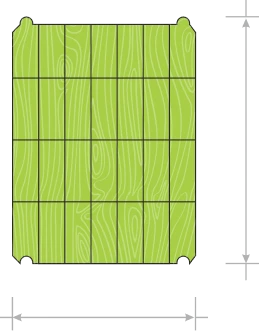

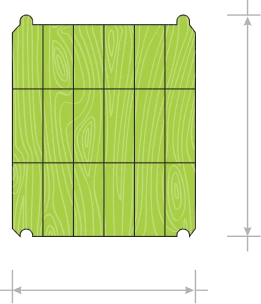

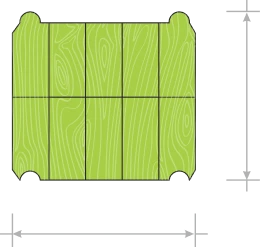

Types

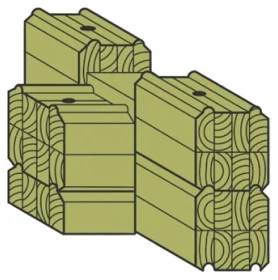

Depending on the customer's preferences, it is possible to manufacture glued laminated timber with the following types of corner and joining connections:

"Cup" joint

This is a classic joint of logs at the intersections of the walls of the wooden house (external, internal, and internal with external walls), as well as at the joints of logs along the length of the wall.

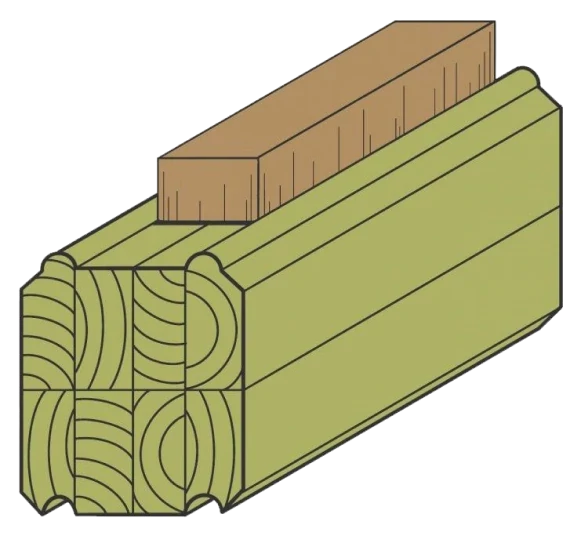

"Butterfly" joint

This type of joint involves locking the logs together by inserting a wooden butterfly-shaped wedge into a pre-prepared factory-made socket. Such a joint is airtight, reliable, and durable, as well as aesthetically pleasing, since the corner joint is done without extending the end of the log beyond the surface of the wall.

Glued

As per customer's preferences, it is possible to manufacture decorative elements from glued milled timber, which is a regular glued timber processed on a special miller machine. Such equipment allows for cutting various patterns, ornaments, moldings, and other decorative elements that can be used in interior or exterior finishing of your wooden house.